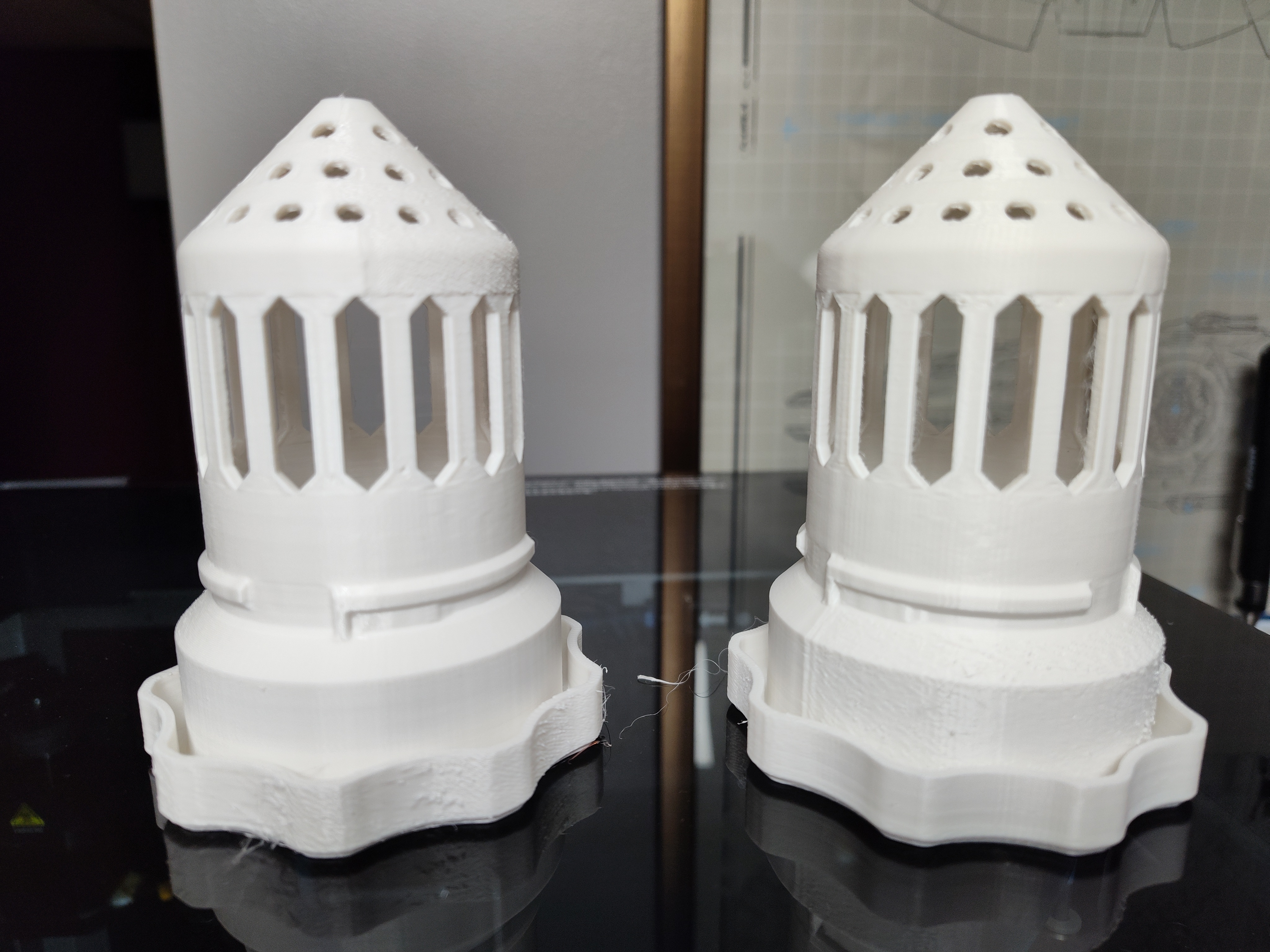

So I sliced and printed a different model, and then rotated 1 by 180°, it is somewhat weird as the lowest part on the right model seems ok but as the wall built up on the inside it was getting the artifacts. The model on the left was getting the artifacts on the outer piece but not the inner.

In rotating the models after, the artifacts are on the opposite side.

I noticed it was starting at the seam, I have the scarf joint on contour, and noticed that “scarf around entire wall” was checked so trying reprinting to see if that is the issue.

Well that was the problem, thanks for everyone’s input.